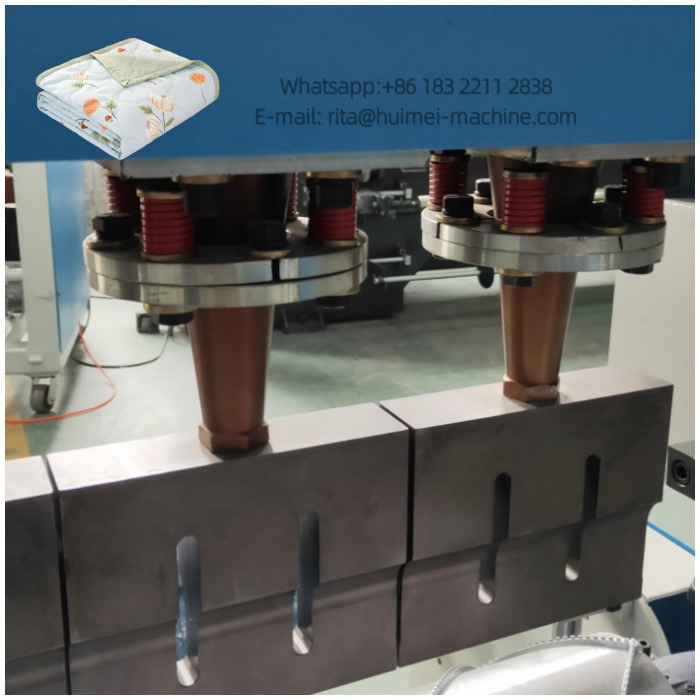

Ultrasonic quilting embossing compound machine for fabric

300-1800 m/ hour embossing speed+ 15/18/20k+custom pattern roller

to meet the processing needs of different fabrics

whatsapp:+ 86 183 2211 2838

E-mail: rita@huimei-machine.com

In the ever - evolving world of textile manufacturing, the ultrasonic quilting embossing compound machine has emerged as a revolutionary device, bringing about a series of advantages that are reshaping the industry.

| Embossing speed | 300-1800 m/ hour, more lighter fabric, the faster speed |

| Quilting Width | 1800 mm/ 2200 mm/ 2400mm/ 2600 mm |

| Power | 4-12 KW |

| Diameter of roller | from 165 mm to 190 mm, 176 mm is standard size |

1. High level safety

Ultrasonic quilting eliminates the need for needles and threads. This means there is no risk of broken needles remaining in the fabric, which could potentially cause harm to consumers. In large - scale manufacturing, this not only safeguards the quality of the products but also ensures the safety of the end - users.

2. Impressive Speed (300-1800 m /hour)

When it comes to production speed, ultrasonic quilting embossing compound machines truly shine. The operation principle of these machines allows for a remarkable quilting speed, and interestingly, the thinner the fabric, the faster the quilting process can be. For manufacturers dealing with large volumes of lightweight fabrics such as silk or thin cotton blends, this means significantly reduced production time. In a competitive market where time - to - market is crucial, the ability to quickly turn out quilted products gives businesses a distinct edge.

3.Customizable Patterns

Changing the pattern on an ultrasonic quilting machine is a breeze. By simply changing the embossing roller, manufacturers can create different quilted patterns. What's more, the embossing rollers can be customized in terms of style and diameter, giving designers and manufacturers the freedom to create unique and exclusive quilted designs. This level of customization is a huge advantage in a market that demands variety and uniqueness, enabling businesses to meet the ever - changing demands of consumers.

4.Versatility in Fabric Processing

Ultrasonic quilting machines are highly versatile when it comes to fabric processing. They are available in a variety of widths to accommodate different fabric sizes, making them suitable for a wide range of applications, from small - scale handicrafts to large - scale industrial production. Additionally, different frequencies to meet various types of fabrics, whether it's a thick denim or a sheer lace. This adaptability allows manufacturers to work with diverse materials, expanding their product offerings.

5.Environmentally Friendly - No Pollution

Ultrasonic quilting machines stand out as an eco - friendly choice. They operate without the use of any adhesives or other binding materials. With ultrasonic quilting, not only are the production facilities free from the fumes and residues associated with adhesives, but the final products are also free from any potentially harmful substances, making them more suitable for use in applications where health and environmental safety are top priorities, such as in the production of medical textiles or organic bedding.

6. High Reliability and Durability

The quilting achieved by ultrasonic quilting embossing compound machine is highly reliable and durable. The ultrasonic waves create a strong bond between the fabric layers, ensuring that the quilted product can withstand regular use and washing without fear of seams breaking or the layers separating. This high level of Firmness means that products have a longer lifespan, reducing the need for frequent replacements. For manufacturers, this translates into fewer returns and higher customer satisfaction. Whether it's a heavy - duty industrial quilt or a delicate home decor item, the integrity of the quilting is maintained over time.

In conclusion, ultrasonic quilting machines are a remarkable innovation in the textile industry. With their combination of safety, speed, environmental friendliness, reliability, automation, versatility, and customizability, they are set to be the go - to choice for textile manufacturers looking to stay ahead in the competitive global market.

we attached some patterns design and final products photo for your reference.