From raw materials to finished quilts, automated production

Used in conjunction with quilting machines to form a complete industrial chain

Easy to operate and efficient

whatsapp: +86 18322112838

E-mail: rita@huimei-machine.com

As a large quilt factory, I think you must want to achieve one-stop automated production from fiber raw materials to quilts.

Huimei wadding production line is a humanized production line that can be configured with different equipment according to the specific requirements of customers. The finished products can be used in quilts, mattresses, sofas, clothing and other industries.

| Model | HM-Q850 | HM-Q1230 | HM-Q1850 | HM-Q2000 |

| Floor size | 15*10*3 m | 15*10*3 m | 16*10*3 m | 16*10*3 m |

| Product width | 2800-3000-3200-3600-4000-6000 mm optional | |||

| Wadding density | 40-1200 gsm | |||

| Output | 100-150 kg/h | 150-200 kg/h | 250 kg/h | 300 kg/h |

| Total power | 28 kw | 33 kw | 38 kw | 45 kw |

| Standard | material based on 3-15 D | |||

| Finished product | 2-3.2 cm | |||

The complete wadding production line includes the following equipment:

1) Opening machine

It opens the compressed fiber raw materials into fluffy fibers and conveys them to the cotton feeding box

2) Cotton feeding box

Stores the raw materials conveyed by the opener and conveys them to the carding machine evenly

3) Carding machine

Further opens and combs the raw materials conveyed from the cotton feeding box into a mesh fiber layer, and passes through the random roller to make the fibers on the fiber layer more closely intertwined, and conveys the fiber layer to the next process

4) cross lapper /Laying machine

The cotton layer conveyed by the carding machine is folded back and forth to continuously form a fiber layer with a certain width and thickness

5) Automatic quilt filling machine

The obtained fiber layer with a specific width, thickness and length is loaded into the quilt cover through the conveyor belt

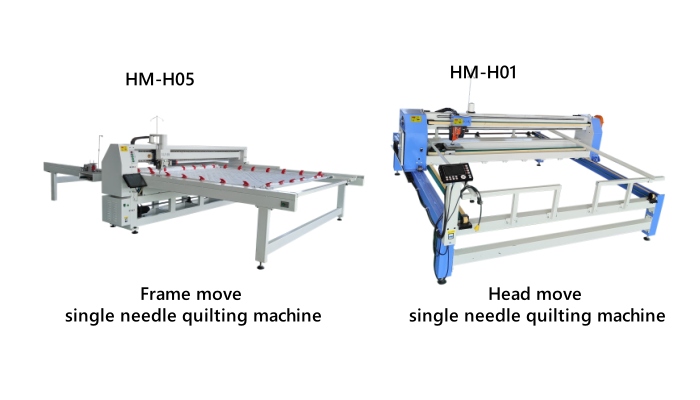

6) Quilting machine

Put the quilt cover on the quilting machine frame for quilting.

7) it can work with single needle quiting machine to achieve one step from raw material to finished quilts,. comforters.