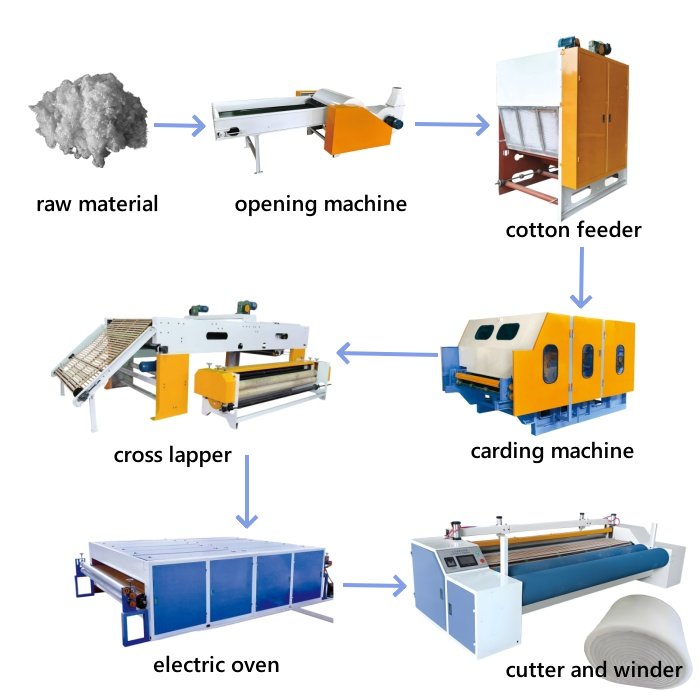

Glue free cotton production line

The finished product is soft, strong, washable, environmentally friendly,

and is an excellent filling material for bedding.

The whole production line has optional configuration and adjustable speed.

Whatsapp:+86 183 2211 2838

E-mail: rita@huimei-machine.com

High efficiency, environmental protection and low cost are the pursuit of modern production. Our glue free cotton production line can meet the above requirements.

The finished products of the glue free cotton production line are a rational choice for making soft fillings such as quilts, cushions, sofa cushions, etc. due to their good

breathability, warmth retention, environmental protection, strong resilience, aging resistance, and water resistance. It can also be used in high-end bras, baby products

and other fields.

| Model | HM-P02850 | HM-P021230 | HM-P021850 | HM-P022000 |

| Floor size | 15*10*3 m | 15*10*3 m | 16*10*3 m | 16*10*3 m |

| Product width | 2800-3000-3200-3600-4000-6000 optional | |||

| Wadding density | 40-1200 gsm | |||

| Output | 100-150 kg/h | 150-200 kg/h | 250 kg/h | 300 kg/h |

| Total power | 96.75 kw | 101.75 kw | 104.75 kw | 106.75 kw |

| Standard | Based on 7D*64 mm polyester riber pver 70% | |||

| Finished product | polyester wadding roll, non-glue cotton | |||

The entire glue free cotton production line is variable-frequency and speed-adjustable, and is easy to operate. Different configurations can be adopted according to customer needs.

Our glue-free cotton production line has achieved a gorgeous transformation from compressed fibers to glue-free cotton rolls or glue-free cotton sheets. It repeatedly opens the 7D*64mm fibers,combs them into a mesh fiber layer by carding machine, and squeezes them through random rollers to make the fibers more tightly interwoven. Then, the fibers are repeatedly folded by the cross lapper to form a fiber layer with a certain width and thickness. Under the high temperature of the electric oven, the low melting point chemical fiber in the raw material bonds all the fibers together like glue, but it does not contain chemicals and is more environmentally friendly, making the fiber layer more tensile and resilient.

Finally, under the action of the cutter, the edges are trimmed, and according to the settings, the cutter automatically cuts off the fiber layer, and two coarse cloth rollers are used to roll the fiber layer into a glue free cotton sheet or glue free cotton roll with a specific length and width.

Manufacturers from all over the world are welcome to customize their own glue free cotton production line. We are willing to configure different product lines for you according to your specific needs. Contact us to start your customization journey!