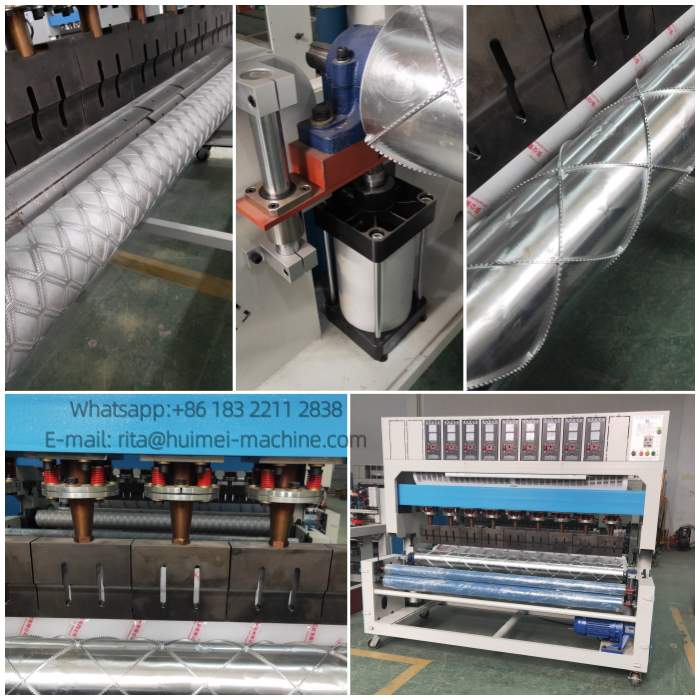

Fully Automatic Ultrasonic Quilting Machine

No needle and thread, no pinholes and moisture proof

It is suitable for Industries that require product sealing: moisture-proof pads, medical supplies, thermal insulation houses,electric heating blankets etc.

Whatsapp:+ 86 183 2211 2838

E-mail: rita@huimei-machine.com

Fully Automatic Ultrasonic Quilting Machine--High Speed Quilting Machine

Fully Automatic Ultrasonic quilting Machine is an efficient and environmentally friendly textile processing equipment, which is widely used in clothing, home textiles, automotive interiors, medical supplies and other fields. Its core principle is to use the heat energy generated by high-frequency vibration of ultrasound to partially melt and bond the material without the need for traditional sewing thread or glue.

| Product Name | fully automatic ultrasonic quilting machine |

| Efficient width | 1550 mm, 1800 mm, 2000 mm, 2200 mm, 2400 mm, 2600 mm, 3000 mm or custom size |

| Ultrasonic frequency | 15 k, 18 k, 20 k is available , it is depends on the fabric weight and pattern type |

| Quilting speed | 300-1800 m/hour , 300 meters of fabric weighs 300/400g. The lighter the fabric, the faster the speed. |

| Power | AC 380V , if you have other requirement, pls contact us to confirm |

The feature of fully automatic ultrasonic quilting machine:

1)Needle-free and no thread, environmentally friendly and efficient

Ultrasonic quilting does not require needles and threads, and directly uses high-frequency vibration to fuse the fabric, reducing thread consumption. At the same time, it can avoid problems such as thread breakage and skipped stitches, and reduce the defective rate; it reduces the thread processing process and simplifies the production process; it conforms to the trend of environmental protection and reduces material waste.

2) High-speed production, improved efficiency

300-1800 m/h embossing speed, suitable for mass production, shortened delivery time; can also be used for one-time composite processing of multi-layer materials (such as fabric + filling cotton).

3) Strong material applicability

Chemical fiber fabrics (polyester, nylon, etc.): Ultrasonic fusion is the best

Non-woven fabrics and film materials: Strong bonding, no burrs on the edges

Composite fabrics: Can be quilted and embossed at the same time

4)The quilting effect is diverse and precise

The flower roller mold can be customized to achieve embossing or quilting of complex patterns

The bonding part is firm and beautiful, without the convex feeling of traditional stitches, suitable for fields with high precision requirements

5)High degree of automation

The configured poweless feeder and automatic rolling machine reduce labor costs.

High repetition accuracy is conducive to the consistency of products in the same batch

The package of fully automatic ultrasonic quilting machine

1: one set of ultrasonic quilting machine including main machine, powerless feeder and automatic rolling machine;

2: automatic cotton feeder and side cutting system is optional;

3. our standard packing is bulk packing with plastic cover;

4: if you want to order wooden box packing, it will be ok.

The service of fully automatic ultrasonic quilting machine

1: Recommend suitable models and configurations according to specific requirements;

2: MOQ: 1 set

3: Strict quality inspection before shipment

4: 7*24 hours online service, if necessary, video is available