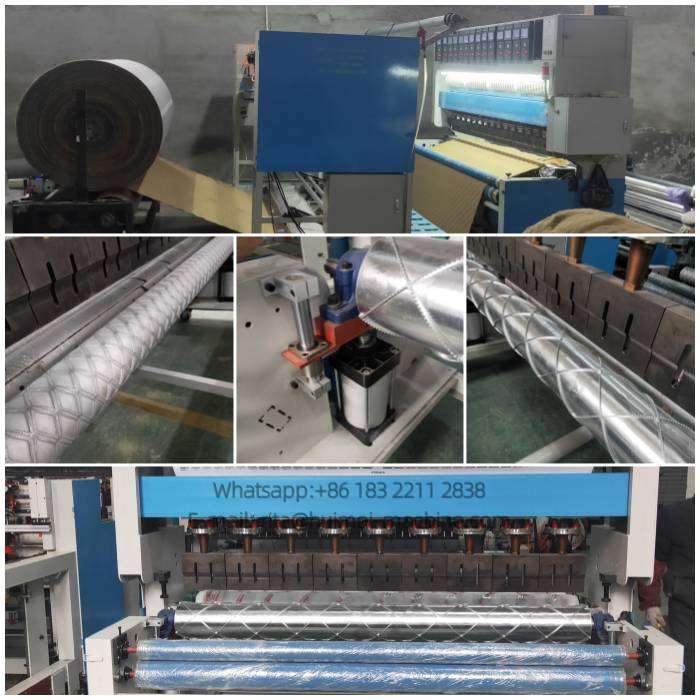

Ultrasonic quilting machine with cutter

Configure side cutting system can cut the fabric to certain length

Custom flower roller pattern and diameters

High speed and various width

Whatsapp: + 86 183 2211 2838

E-mail: rita@huimei-machine.com

Ultrasonic quilting machine with cutter--Revolutionizing Textile Production

--Innovative, Eco-Friendly, and High-Speed Fabric Bonding Technology

Ultrasonic quilting machines with cutter are transforming textile manufacturing with their speed, versatility, and eco-conscious design. Whether you’re producing high-end home décor or medical-grade fabrics, this technology delivers unmatched efficiency and quality. It is an advanced industrial device that uses high-frequency ultrasonic vibrations to bond layers of fabric, padding, or nonwoven materials without needles, threads, or adhesives. This technology is widely adopted in industries such as apparel, home textiles, automotive interiors, and medical supplies etc.

| Product Name | ultrasonic quilting machine with cutter |

| Quilting speed | 300-1800 m/hour based on different fabric thickness and weights, the lighter and the faster |

| Quilting width | 1550 mm, 1800 mm, 2200 mm, 2400 mm, 2600 mm, 3000 mm etc. |

| Ultrasonic frequency | 15k, 18k, 20 k based on fabric weights and patterns |

| Flower roller | diameter 165mm-190 mm, 176 mm is standard size. the pattern can be customized |

| Power | AC 380V 4-12kw. If you have special requirements please let us know |

The Main Features of ultrasonic quilting machine with cutter

1) Fast quilting speed and low consumption

Ultrasonic quilting does not require needles and threads. It directly uses ultrasonic high-frequency vibration to bond fabrics. Multiple points are operated at the same time. It is fast and efficient. Depending on the fabric, it can reach 300-1800 meters per hour. It is suitable for enterprises with high production requirements.

2)Versatile Material Compatibility

Ultrasonic quilting machine can work on Synthetic fabrics (polyester, nylon, PP, PE), Nonwoven fabrics, laminated films, and composite materials and Foam, batting, or padding layers (bonded in a single pass).

Note: Not suitable for natural fibers (cotton, wool) due to non-thermoplastic properties.

3) Wide range of applications of finished goods

| Home textile | Quilt, bedspreads, pillows cover, curtains, mattress toppers |

| Medical | Surgical gowns, masks, disposable drapes, wound dressings |

| Clothings and bags | Puffer jackets, synthetic leather goods, reusable shopping bags |

| Packaging | Nonwoven gift wraps, padded mailers, eco-friendly pouches. |

| Automotive | Seat upholstery, headliners, door panels, trunk liners. |

4) High Precision & Customization--design flexibility

- Customizable embossing patterns (via interchangeable rotary wheels).

- Seamless integration of logos, decorative motifs, or functional textures.

- Cut to a certain length as required

The Package of ultrasonic quilting machine with cutter

1. one whole ultrasonic quilting machine with cutter including ultrasonic quilting machine, powerless feeding and automatic rolling machine (standard content) ;automatic cotton feeder and side cutting system is optional

2. bulk packing is standard and will fix them into the container.

3. wooden box package is avaiable