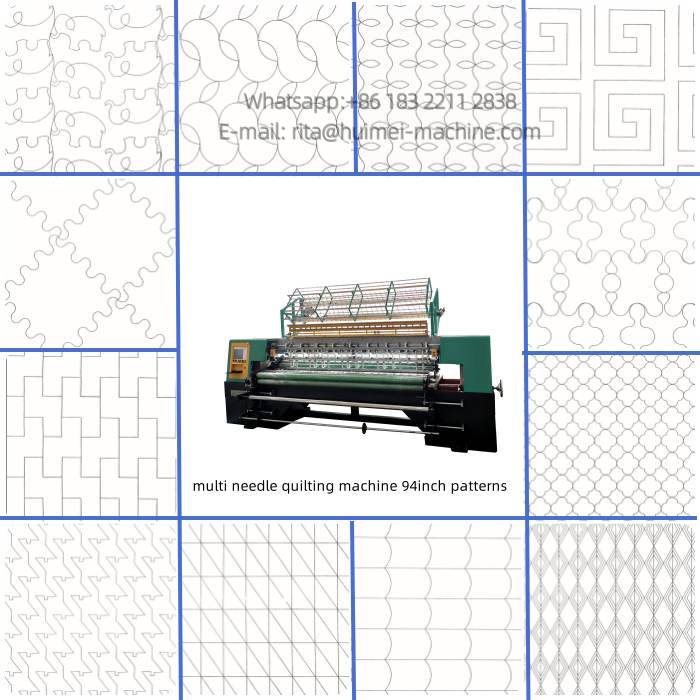

CNC computerized multi needle quilting machine 94inch

Not only 94 inch, but also 64 inch, 66 inch, 74 inch, 96 inch, 110 inch multi needle quilting machine

No need to stop the machine to modify the compensation pattern

Automatic stop in case of thread break

Whatsapp:+8618322112838

E-mail: rita@huimei-machine.com

CNC computerized multi needle quilting machine 94inch

How to choose a multi-needle quilting machine with stable performance, diverse functions and simple operation is a difficult problem that plagues manufacturing companies.

As a professional quilting machine manufacturer, Huimei has been working hard to improve technology to provide customers with a variety of multi needle quilting machine 94inch.

There are 2 rows and 3 rows needles multi needle quilting machine 94 inch to meet the production needs of different styles.

| Model | HM-M0166 | HM-M94 | HM-N0196 |

| Needle number | 132 | 108 | 192 |

| Needle distance | 25.4 mm | 25.4 mm | 25.4 mm |

| Quilting width | 1680 mm | 2400 mm | 2440 mm |

| Quilting thickness | 1000 gsm | 1000 gsm | 1000 gsm |

| Quilting speed | max 850 needles per minute | max 850 needles per minute | max 850 needles per minute |

We strongly recommend the multi needle quilting machine 94 inch, because it has the following features:

1) Diversity of quilting patterns

A large number of quilting patterns are prepared, including both tight small patterns and loose large patterns. Operators can arrange needles according to the instructions, which is easy to operate. You can also edit existing patterns or draw new patterns on the host, and your creativity is not limited.

2) Diversity of quilting methods

360-degree omnidirectional quilting and independent pattern interval quilting functions, seamless switching between continuous quilting and single-step quilting, provide favorable support for the realization of pattern diversity

3) Advanced configuration

Adopt advanced CNC control solutions and mechanical manufacturing technology, powerful and stable WINDOWS XP operating system, PCI motion control card, can be adapted to any configuration computer platform; rollers and saddles use brand servo drive equipment, light vibration and low noise

4) User-friendly operation

a. Quilting simulation display, real-time monitoring of quilting process;

b. Automatic shutdown function when thread breaks to avoid waste;

c. Infrared sensor to effectively protect operator safety;

d. Pattern compensation function to effectively avoid pattern deformation caused by thickening of quilting materials, without stopping the machine and delaying production;

e. Shutdown for scheduled output and shutdown when the bottom line is used up can be set;

f. Integrated design, small footprint;

g. All metric design to solve the problem of parts source and facilitate maintenance;

h. All mechanical parts are oil-free design, no need to refuel, convenient and clean.