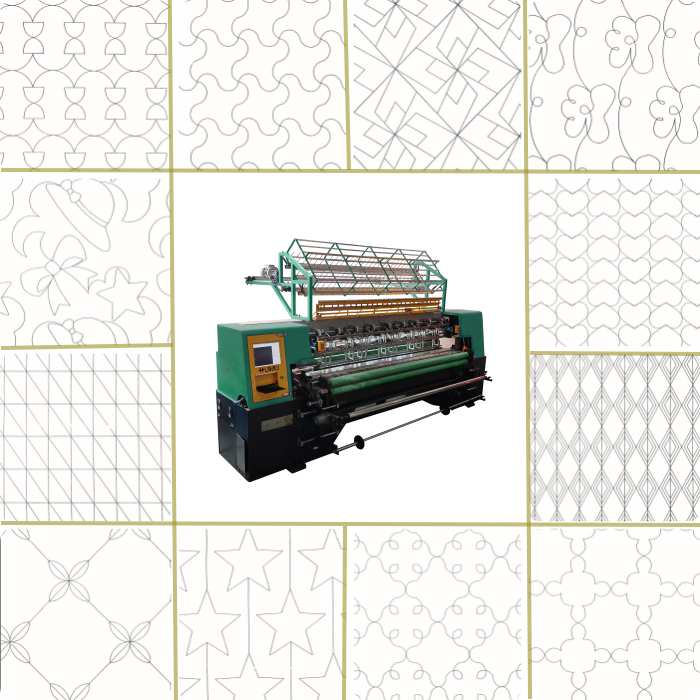

Lock stitch multi needle quilting machine for mattress

Multiple needles run at high speed simultaneously, with large output (150-200 m/hour)

Built-in multiple patterns and free to add new patterns

CNC control and brand servo drive saddle and rollerq

Whatsapp:+ 86 183 2211 2838

E-mail: rita@huimei-machine.com

Multi needle quilting machine for mattress has become a trend in large-scale production.With its own characteristics, Its share in the quilting industry is increasing year by year.

1)multi needle quilting machine for mattress form lock stitch

a lock stitch is created by interlacing two threads (needle thread and bobbin thread), resulting in a more secure, stronger stitch, and difficult to pull apart. Therefore, the mattress produced by the multi-needle quilting machine can be washed.

2)Intelligent and user-friendly design

a.With various specifications, customers can choose multi needle quilting machine for mattress of different sizes according to their actual production needs to avoid waste or the situation where the quilting width cannot meet the production needs.

| Model | HM-M0164 | HM-M0166 | HM-M0172 | HM-M0194 | HM-M0196 |

| Needle number | 128 | 132 | 144 | 188 | 192 |

| Neddle distance | 25.4 mm | ||||

| Process width | 1625 mm | 1680 mm | 1828 mm | 2400 mm | 2440 mm |

| Quilting speed | 50-850 RPM | ||||

| Quilting thickness | 1000 gsm | ||||

| Power | AC 380V 50HZ | ||||

b. CNC control solutions and advanced mechanical manufacturing technology improve the performance,speed and output of the machine.

c.The saddle and roller adopt brand servo drive equipment to ensure the precision and stability of quilting and low noise.

d. max quilting speed can reach 850 RPM , adjustable needle distance and 2 or 3 rows needle is optional, ensure the multi needle quilting machine for mattress can quilting more types of patterns, unlimited design.

e. Built-in multiple patterns, from simple lines to complex flowers and animals, can be selected from the host. The operator can also draw new patterns directly on the host, without the need for a separate computer, making the operation easier. It also has embroidery function and can input DST embroidery files.

f. Pattern compensation function can effectively solve the problem of pattern deformation caused by thickening of quilting materials.

g.The left and right limit over-travel shutdown and thread breakage automatic shutdown functions prevent the quilting from deviations due to accidents and resulting in defective products.

h.Infrared sensors can sense the approach of human hands and protect the personal safety of the operator.

i.Metric design makes it easier for users to find replacement parts locally when they need to replace accessories during subsequent use, without having to wait for a long time and delay production.