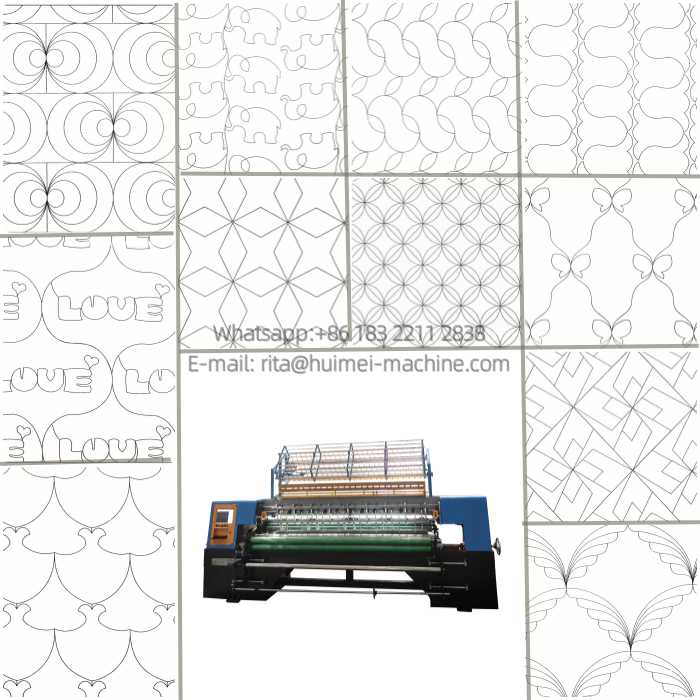

quilting machine multi needle single head

Advanced CNC control and mechincal manufacturing technology

Pattern compensation function solves the problem of pattern deformation caused by material thickening

Infrared sensor safety protection device.

whatsapp:+86 18322112838

Email: rita@huimei-machine.com

Innovative Multi Needle Quilting Machine Single head: Precision, Versatility, and Durability

In the evolving world of textile manufacturing and creative design, efficiency, precision, and adaptability are paramount. Our Multi Needle Quilting Machine Single Head stands at the forefront of innovation, engineered to meet the demands of professionals across industries—from fashion designers and home décor artisans to industrial textile manufacturers. Combining cutting-edge technology with user-centric design, this machine redefines what’s possible in quilting.

Why our multi needle quilting machine single head is popular?

1.A variety of effective widths are available (64 inch,66 inch, 72 inch, 94 inch ,96 inch or 110 inch or custom size)

| Model | HM-M0164 | HM-M0166 | HM-M0172 | HM-M0194 | HM-M0196 |

| Needle number | 128 | 132 | 144 | 188 | 192 |

| Needle distance | 25.4 mm | 25.4 mm | 25.4 mm | 25.4 mm | 25.4 mm |

| Process width | 1625 mm | 1680 mm | 1828 mm | 2400 mm | 2440 mm |

| Quilting speed | max 850 RPM, 150-200 m/ hour | ||||

| Quilting thickness | 1000 gsm | ||||

2. The needle bar spacing is 25.4mm, and with the option of 2 or 3 rows of needles, more patterns of different specifications can be processed

3.Advanced Lock-Stitch Mechanism

Quilting machine multi needle single head’s lock-stitch system ensures superior seam durability, making finished products resistant to fraying and capable of withstanding repeated washing. Ideal for bedding, apparel, and upholstery, this feature guarantees long-lasting quality that maintains its integrity even under heavy use.

4.CNC-Controlled Precision

Powered by a computerized numerical control (CNC) system, the machine delivers pixel-perfect accuracy for intricate patterns and repeatable designs. The intuitive interface allows operators to program stitching paths, adjust speeds, and monitor workflows in real time, ensuring consistency across small batches or large-scale production runs.

5.Servo-Driven Carriage Rollers

Equipped with servo motors, the Saddle and rollers provide robust yet silent operation. This technology minimizes vibrations and noise while maximizing energy efficiency, creating a calmer, more sustainable workspace. The metric-standard components further simplify maintenance, reducing downtime and operational costs.

6.Versatile Quilting Modes

Adaptability lies at the heart of this machine, offering multiple quilting styles:

Continuous Quilting: Perfect for large-area projects like quilts or curtains.

Single-Step Patterns: Execute complex designs with pinpoint accuracy.

360° Free-Motion Quilting: Unleash creativity with unrestricted directional stitching.

Independent Spaced Motifs: Create unique, non-repeating patterns for bespoke products.

7. Onboard Design Studio

With 100+ preloaded patterns and a built-in touchscreen interface, users can select from an extensive library or sketch custom designs directly on the machine. This eliminates the need for external software, streamlining the design-to-production process.